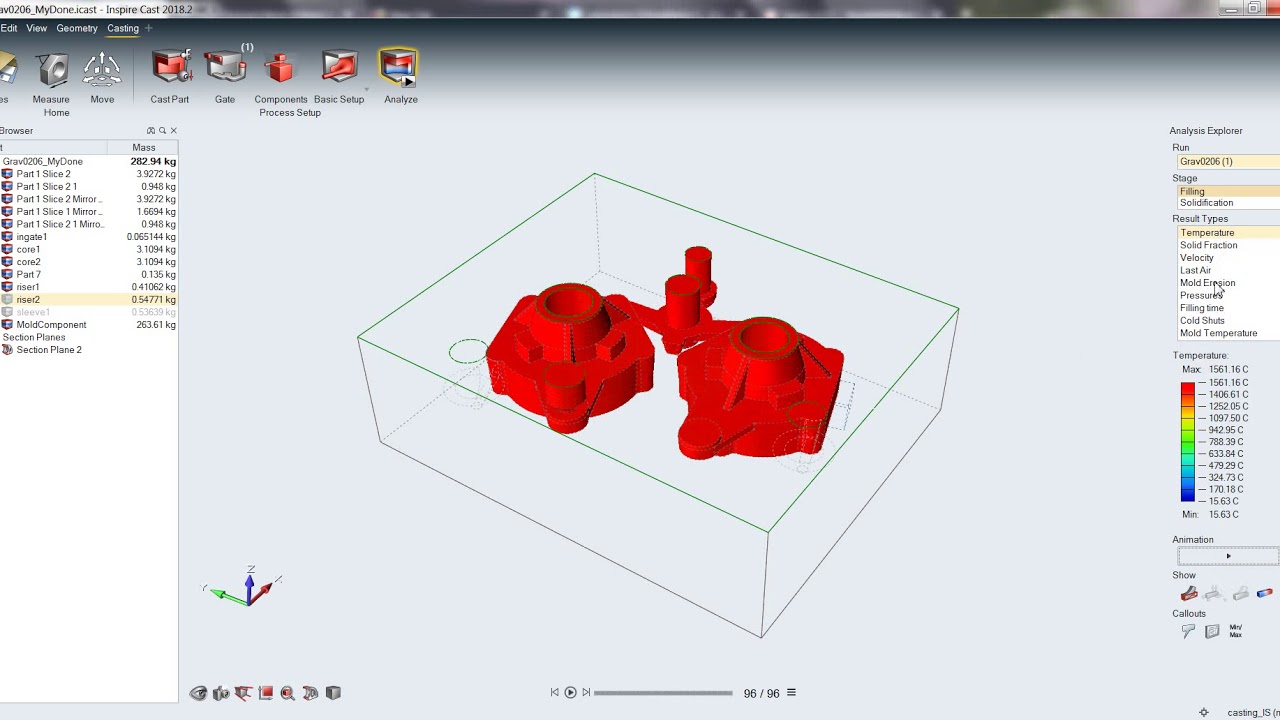

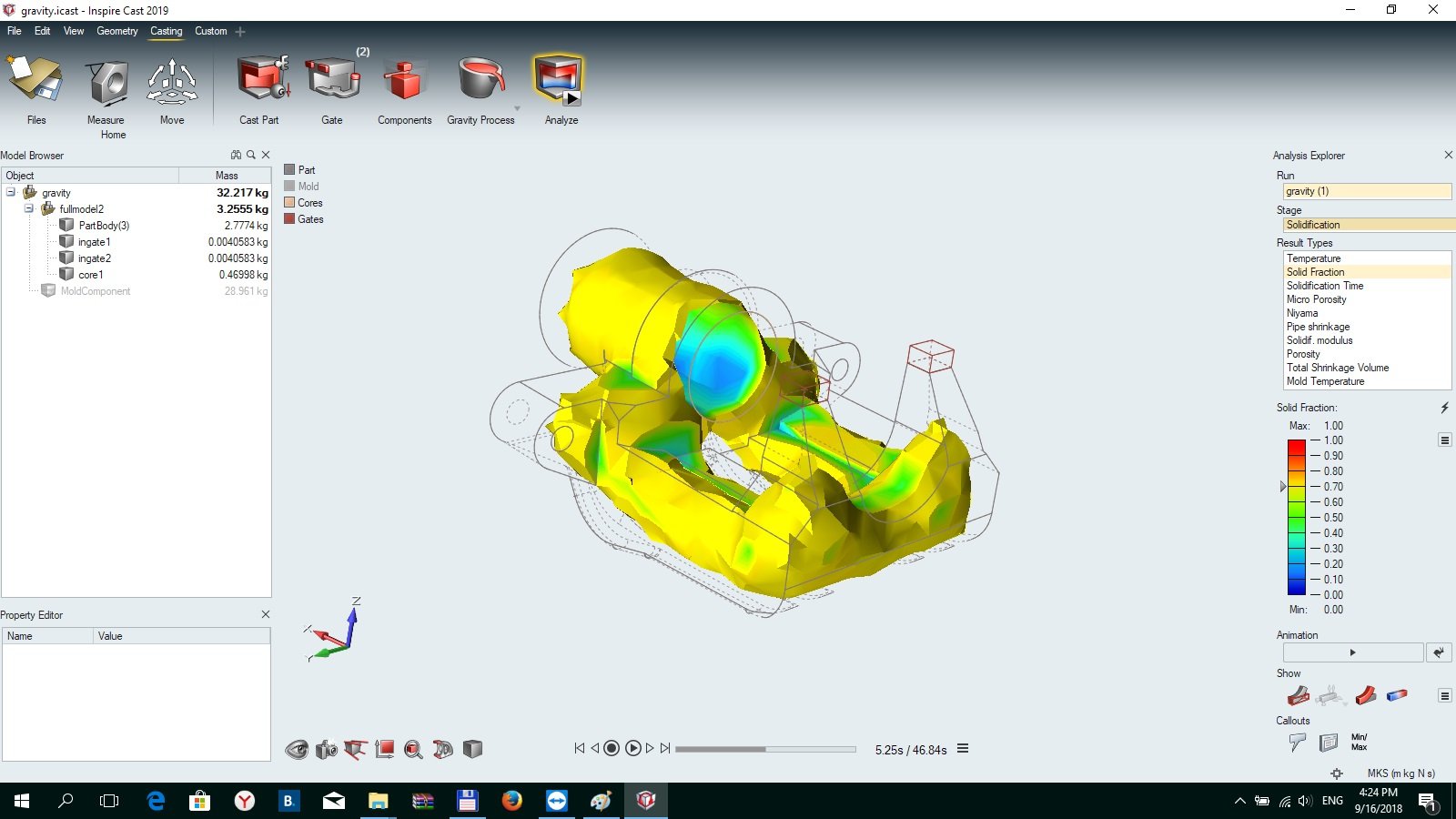

The flywheel simulation sand-casting process for two different conditions such as top gating and side gating systems to predict the filling time, liquid metal velocity, mould erosion, solid fraction, porosity, and cold shuts. The paper showcases the process and inferences drawn by creating casting simulations for a flywheel component manufactured by sand casting. Moreover, it is of great use to understand the probable locations where internal defects such as shrinkage porosity and sand inclusions might occur without prototypes, thereby saving time and money.

This software can simulate at high speed because it creates a simulated model in just five steps.Running simulations for casting have gained popularity in industries since it helps study mould filling, solidifying metal, and cooling part in the cast. This software helps users to identify and correct possible defects, such as defects due to liquid flow, such as cold welding, air inclusions, inclusions of inclusions and slag, and defects due to freezing, including large voids, small voids, gas gaps, residual stresses, cracks.

This process is the oldest known process for obtaining the desired shape of metals.Īltair Inspire Cast, previously published as solidThinking Click2Cast, is simulation software that is a casting process that provides a simple but functional environment for creating and optimizing production parts. Altair Inspire Cast’s innovative experience enables users to improve product quality and develop better products with just a few hours of training.Ĭasting is the art of shaping metals and alloys by melting, pouring the melt into a chamber called a mold, and then cooling and solidifying it according to the shape of the mold chamber. Guided Process Templates offer 5 simple steps to simulate gravity nozzle, gravity sand, investment material, high pressure die casting, low pressure and inclined casting. It is the only tool that appeals to both beginners and experts, from product designers to foundry engineers.Įven in the initial design phase, users can visualize typical casting defects, such as air inclusions, shrinkage porosity, cold connections, and shape deterioration, and correct them without costly post-correction. Altair Inspire Cast 2021 software is a fast, simple, accurate, and affordable casting simulation environment that focuses on producing high-quality components more cost-effectively through a highly intuitive user experience.

0 kommentar(er)

0 kommentar(er)